[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

Parti di ricambio gratuite

Parti di ricambio gratuite

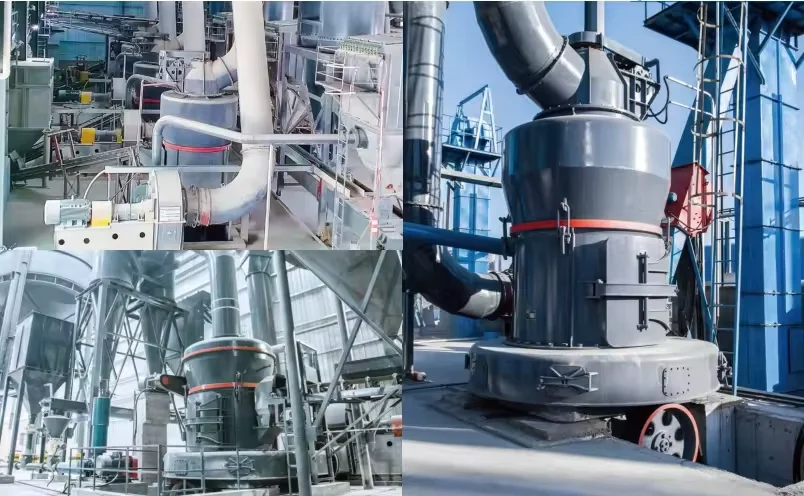

Produce high-quality industrial milling powders efficiently using the ZENITH Raymond mill. Ideal for non-metallic mineral processing, it delivers precisely classified particulates.

Common output sizes range from 30-400 mesh (0.5-0.04 mm), meeting the fineness demands of industries like ceramics, construction, chemical and others. The adjustable analyzer classifier flexibly caters to various mesh specifications.

Inside the spinning grinding chamber equipped with Variable-frequency host, mineral lumps are ground into micro-fine pieces by impact and friction from multiple grind rollers and grinding rings. This ensures over 80% of products pass 200 mesh.

Compared to ball mills, it offers higher efficiency with lower power consumption. The automatic hydraulic lubrication system lowers maintenance costs. Processing 1-2 tons per hour, it ensures large-volume and consistent production of high-demand powder materials.

As a premium pulverizing solution, the Raymond mill boosts output for users seeking ultra-fine milling capabilities. Contact ZENITH to discuss customized systems for your manufacturing needs.

raymond mill for silica are indispensable machines for producing high-purity limestone powders in various industries. Our raymond mill for silica vertical roller mills and ball mills are suitable for dry or wet limestone processing applications.

Limestone powder has many industrial and commercial uses due to its chemical properties. Here are some common applications of limestone powder:

Cement production - Limestone is a chief component in cement formulations, providing calcium during curing processes.

Concrete and mortar - Finely ground limestone is added as an aggregate to concrete and mortar, increasing workability.

Soil amendment - Limestone powder raises soil pH and supplies calcium for land remediation and agriculture.

Construction filler - It is used as a white powder filler in paints, plastics, rubber products, pipe coatings.

Paper manufacturing - Acts as a pigment filler to improve opacity and surface properties.

Water treatment - Limestone neutralizes acidity and heavy metals in industrial waste streams.

Flue gas desulfurization - Captures sulfur dioxide emissions from coal combustion in power plants.

Agricultural products - Provides calcium supplementation for livestock feeds and fertilizers.

Toothpaste/pharmaceuticals - Contributes calcium and acts as an inert abrasive.

Food and beverage processing - Approved as a whitening and anti-caking agent.

The particle size can vary from micron-scale powders for environmental uses to coarser forms in construction aggregates.

Click to know more about raymond mill for silica >>>

The particle size of limestone powder can vary depending on the intended application, but some common sizes include:

Coarse Powder: 200-600 microns (often used as filter media or soil amendment)

Medium Powder: 75-200 microns (for paint fillers, plastics, concretes)

Fine Powder: 20-75 microns (paper coatings, mining applications)

Ultra Fine Powder: Below 20 microns or 5-10 microns (flue gas desulfurization, environmental uses)

Super Fine Powder: Below 5 microns (high performance coatings, specialized chemical uses)

In general:

Larger sizes (>200 microns) for bulk fillers, construction materials, filters

Medium sizes (75-200 microns) for most industrial uses including ceramics, plastics

Fine sizes (20-75 microns) where particle size is important like paper, coatings

Ultra fine (5 microns and under) required for niche specialty chemicals or environmental applications

The exact particle size distribution and fineness needed depends on the specific process and performance requirements. The powder is processed to be consistent and meet specifications.

High Efficient Ore Grinding Mill Raymond Mill For Silica Free Shipping With Capacity 10-35 Tph

This type grinding powder is mainly used for grinding the material with middle and low hardness, below 6% moisture, and the material should be non-explosion and non-flammability, such as: calcite, chalk,limestone, dolomite, kaolin, bentonite, steatite, mica, magnetite,iolite, pyrophillite, vermiculite, meerschaum, attapulgite, diatomite,barite, gypsum, alunite, graphite, fluorite, phosphate ore, potassiumore pumice, etc

raymond mill for silica Working principle

1)Raw material which has been crushed to the size specified is elevated into a hopper from which the stuff is loaded. And then through the vibrating feeder ,the materials will transferred evenly and continuously into the grinding powder grinding chamber for powder-processing. After this,the ground stuff is carried by the air from the blower into the classifer for regrinding.The set's airflow system is closely sealed up and circulated under the condition of negative and positive pressure.

2) The grinding powder is driven by rotation of the central axle through decelerator ,with the up end of the axle connecting to a quincunx-rack upon which the grinding equipment is fixed. The whole set equipment turns together with the axle along the grinding ring while the rollers rotate driven by the fractional force .A set of shovel are installed at the lower end of the quincunx-rack.While turning together with the rollers ,the shovels shed the stuff onto the gap between the rollers and the ring ,and that's where the stuff layer forms .The rotating rollers ,while turning together with the ring ,grind the stuff layer into powder.

3) The turning speed of the impeller can be adjusted to the requirement of the fineness of powder products .

4)grinding powder plays an important role in ensuring the function of the grinder . As the high-speed revolving air current mixed with ground stuff is flown into the cyclone-collector ,the ground stuff is separated from the air-current

Specifications of raymond mill for silica:

| Name & Model | MTW110 | MTW138 | MTW175 | |

| Ring Roller Number(pcs) | 4 | 4 | 5 | |

| Major diameter of roller(mm) | 360×190 | 460×240 | 520×280 | |

| Inner diameter of roller (mm) | 1100×190 | 1380×240 | 1750×280 | |

| Revolving Speed(rmin) | 120 | 96 | 75 | |

| Revolving Speed(rmin) | <30 | <35 | <40 | |

| Final size(mm) | 1.6-0.045, fineness can reach to 0.038 |

1.6-0.045, fineness can reach to 0.038 |

1.6-0.045, fineness can reach to 0.038 |

|

| Capacity(th) | 3.5-10 | 6.5-15 | 13-20 | |

| Overall dimension(mm) | 8625×7933×8642 | 10920×9470×10227 | 12275×9555×9916 | |

| Main unit motor | Model | Y280M-6 | Y315M-6 | Y355M2-8 |

| Power(kw) | 55 | 90 | 160 | |

| Rotate Speed(rmin) | 980 | 990 | 740 | |

| Classifier speed regulating motor (variable frequency motor) |

Model | Y132M-4 | Y180M-4 | Y200L-4 |

| Power(kw) | 7.5 | 18.5 | 30 | |

| Rotate Speed(rmin) | 1440 | 1470 | 1470 | |

| Centrifugal induced draft fan motor | Model | Y250M-4 | Y315-4 | Y315L2-4 |

| Power(kw) | 55 | 110 | 200 | |

![]()

![]()

![]()

|

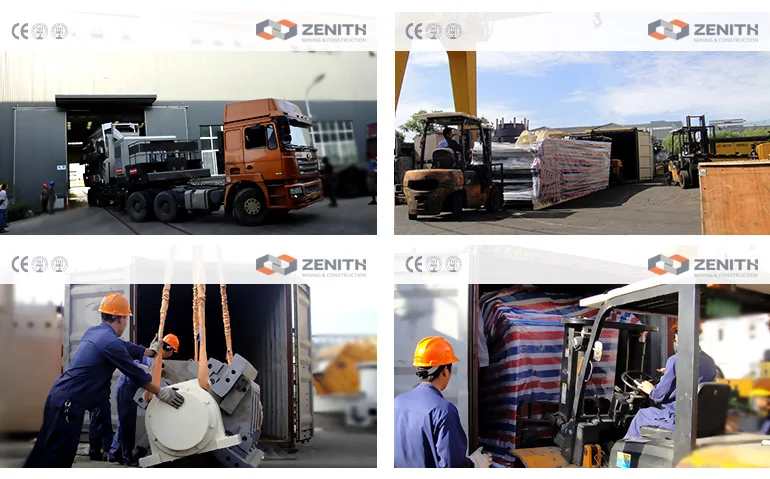

A VARIETY OF TRUSTED EXPERIENCE ZENITH has a variety of professional, reliable and efficient crushing lines all around the world. So customers have great confidence in us. |

|

INFINITE BRAND VALUE What ZENITH is doing is customizing economical and suitable production lines for customers and building brand value. |

|

1200,000 SQUARE METERS OF PRODUCITION AREA 6 large-scale manufacturing bases occupy 1200,000 square meters in total. So quick delivery is a matter of course. |

Founded in 1987, ZENITH has attained 124 patents on crushers and grinding mills over the past 30 years and has more than 30 overseas offices or branches built all over the world. Keeping customers in mind, ZENITH never stops the step forward. Wemake evolution on the outside in order to offer you better equipment; we make revolution on the inside in order to offer you better service.

Ricevi il tuo ordine entro la data prevista o ottieni un indennizzo del 10% in caso di ritardo.

Ogni pagamento fatto su Cooig.com è protetto da crittografia SSL avanzata e rispetta gli standard PCI DSS per la sicurezza dei dati.

Chiedi un rimborso se il tuo ordine non viene spedito, è incompleto o se il prodotto ha dei problemi.

Accedi alla sostituzione gratuita dei pezzi di ricambio e alla copertura delle riparazioni